| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : HHS

Model Number : XK120

Certification : CE

Place of Origin : CHINA

MOQ : 1 SET

Price : USD4000/SET

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 50SETS/MONTH

Delivery Time : 30 working days

Packaging Details : wood package /20/40GP/HC

After-sales service provided : Engineers available to service machinery overseas,Field installation,commissioning and training,Video technical support

Type : Open Mixing Mill

Roller hardness : 50~60HRC

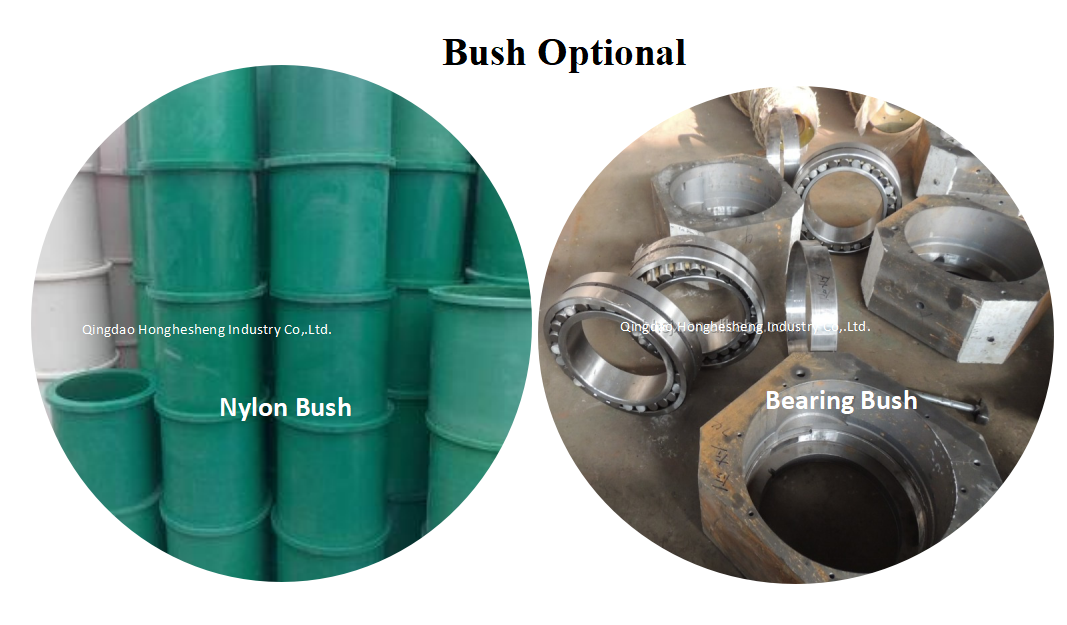

Bush : nylon bush,bearing bush,ball bearing b

Voltage : 220V/380V/450V

Power(w) : 2.2KW

Weight : 500KG

Dimension(l*w*h) : 1400*800*1350mm

Warranty : 2 Year

Condition : New

Engineered to provide unmatched performance for masticating and kneading natural rubber,synthetic rubber , EVA or PVC pellets with various chemical materials.

This machine is mainly used to plastic ,hot mill and mixing mill of natural and synthetic rubber for rubber product factory.

Application:

It is widely used in rubbers and plastics industry for polymer mixing, such as PVC, color master batch. It consists of roll, bearing, gap adjusting device, electric control system, safety device, etc.

Technical parameters:

| Model | X(S)K-160 | X(S)K -250 | X(S)K -360 | X(S)K -400 | X(S)K -450 | X(S)K -550 | X(S)K-660 | |

| Diameter of rolls | 160 | 250 | 360 | 400 | 450 | 550 | 660 | |

| Working length of roll | 320 | 620 | 900 | 1000 | 1200 | 1500 | 2130 | |

| Working speed of front roll | 8.95 | 14.9 | 17.4 | 19.3 | 23.1 | 28.6 | 30 | |

| Fraction ratio of rolls | 1:1.35 | 1:1.1 | 1:1.27 | 1:1.27 | 1:1.27 | 1:1.29 | 1:1.05 | |

| Max.gap(mm) | 5 | 8 | 10 | 10 | 10 | 15 | 15 | |

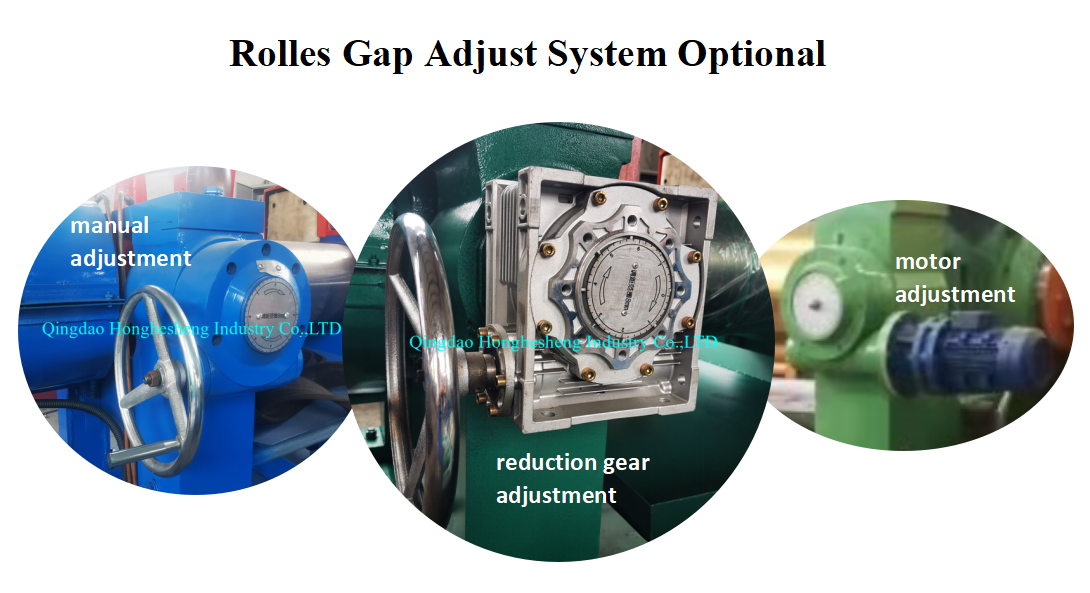

| Nip regulating mode | Manual | Manual | Manual | Manual or Electric | Manual or Electric | Manual or Electric | Electric | |

| Batch capacity(Kg) | 1-2 | 10-15 | 20-15 | 25-35 | 30-50 | 50-60 | 120-140 | |

| Motor | Power | 5.5 | 15 | 30 | 45 | 55 | 90/110 | 180 |

| Motor speed(r/m) | 1440 | 730 | 980 | 740 | 980 | 740 | 740 | |

| Reducer | Full closed type hardened gear speed reducer | |||||||

| Reduction ratio | 43 | 35 | 49.7 | 38 | 47.2 | 35.6 | 126.2 | |

| Overall dimension (mm) | 1120x920 X1295 | 3400x1270 X1620 | 4140x1770 X1700 | 4490x1700 X1750 | 5570x1900 X1750 | 6290x2330 X1780 | 7500x 2630x2060 | |

| Weight (kg) | 1100 | 4200 | 7600 | 9000 | 11500 | 20000 | 26500 | |

Features:

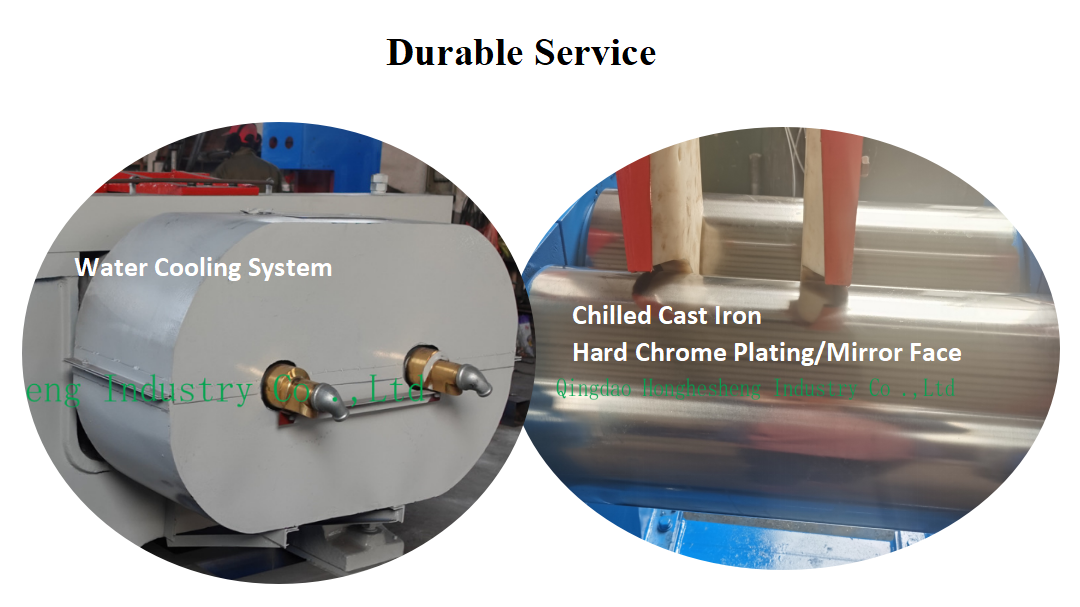

1. Construction of mill rolls: drilled roll, bored roll, grooved roll

2. We can design speed ratio as per customers' formula and processing requirements.

3. Frame, frame cap and base are welded and treated by annealing for stress relieving.

4. Rolls material is chilled cast alloy iron which hardness is reach to 70HB.

5. Brake and emergency stop device can ensure the safety of personnel and equipment.

6. Auto feeding oil or grease lubrication, it is easy to maintain and protect machine.

7. Human nature designed controlling system ensure labor safety.

8. Methods of adjusting roll nip: manual or electric

Intelligent control panel and PLC control system:

1. Real-time data record and export of kneading time, temperature (mixing chamber and front/rear rotors), ram pressure, current, torque and recipe code.

2. The control system can be set up to 20 mixing steps, save 20 recipe spaces.

3. The control system is capable of remote import of the process recipe and data monitoring, communicating with MES via Ethernet communication interface.

4. An Ethernet communication interface and 20% of the control points are reserved. Touch screen is provided.

Detailed Pictures

|

|

Open Mixing Two Roll Mill For Compounding Rubber Images |